Rapid Prototyping: Accelerating Aerospace Innovation

In the aerospace field, where strict requirements are imposed on technical precision, R&D efficiency, and manufacturing costs, rapid prototyping technology is emerging as a core driver of industry innovation. It not only transforms traditional component production models but also plays an irreplaceable role in shortening R&D cycles and optimizing product performance.

The Adaptability of Rapid Prototyping Technology to Aerospace

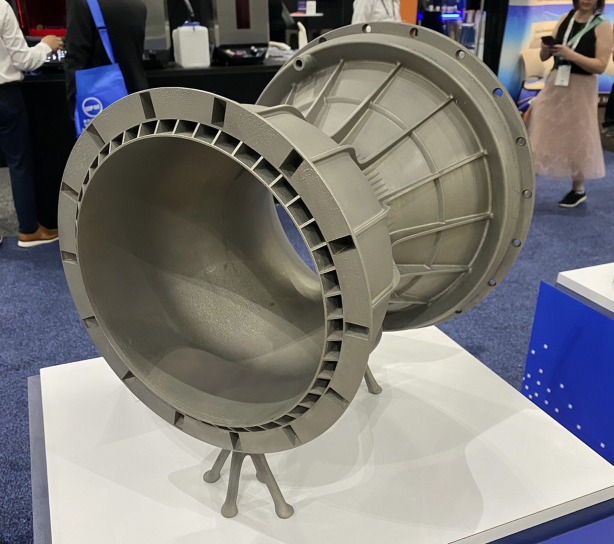

Components in the aerospace sector are often characterized by complex structures, special materials, and extremely high precision requirements, posing challenges to traditional manufacturing processes. However, rapid prototyping technology, with its unique feature of “mold-free, direct formation of complex structures”, perfectly meets the manufacturing needs of aerospace.

Represented by Selective Laser Sintering (SLS) and Electron Beam Melting (EBM), rapid prototyping technologies can process high-performance materials commonly used in aerospace, such as titanium alloys and nickel-based superalloys. Through layer-by-layer material deposition, these technologies can directly produce components with complex internal cavities and hollow structures, eliminating the need for multi-step joining and processing in traditional processes. This not only reduces the number of parts but also avoids stress concentration issues that may arise from welding, forging, and other links, significantly enhancing the structural integrity and reliability of components.

Reshaping R&D and Production Processes

In the R&D phase of aerospace products, the value of rapid prototyping technology is particularly prominent. In the traditional model, developing a new aircraft or spacecraft component from design to prototype verification could take months or even years, with mold manufacturing alone consuming substantial time and costs. In contrast, rapid prototyping technology can shorten the prototype manufacturing cycle to 1/3-1/5 of that of traditional processes.

For example, in the R&D of new engine blades, engineers can use rapid prototyping equipment to produce physical prototypes within days after completing the design via 3D modeling software. These prototypes allow teams to conduct mechanical performance tests, aerodynamic analysis, and other verification work. This rapid iteration capability enables R&D teams to test multiple design schemes in a short time, optimize structural parameters promptly, and significantly reduce R&D risks. The European Space Agency (ESA) extensively adopted rapid prototyping technology to manufacture key component prototypes during the development of the Ariane 6 rocket, shortening the overall R&D cycle by nearly 20%.

Rapid prototyping technology also excels in small-batch production. For non-standard components required by special aircraft models or experimental spacecraft, traditional mold manufacturing faces difficulties in cost amortization due to low demand. Rapid prototyping technology, however, enables “on-demand production” without high mold investment, significantly reducing the manufacturing costs of small-batch components. SpaceX, during the early testing phase of the Falcon 9 rocket, produced various small-batch components such as valves and brackets using rapid prototyping technology, effectively controlling test costs.

Dual Breakthroughs in Performance Optimization and Cost Control

Rapid prototyping technology not only improves the production efficiency of aerospace components but also achieves dual breakthroughs in performance optimization and cost control.

In terms of performance, the combination of topology optimization design and rapid prototyping technology enables the production of lightweight structures that are unattainable with traditional processes. For instance, aircraft landing gear brackets and spacecraft propulsion system components manufactured using rapid prototyping technology can reduce weight by 15%-30% while maintaining strength. For aerospace products, this translates to lower fuel consumption, longer endurance, or larger payloads. Data from Boeing shows that after adopting rapid prototyped components in some aircraft models, the weight per aircraft decreased by approximately 4%, saving airlines tens of millions of yuan in fuel costs annually.

In cost control, rapid prototyping technology optimizes the entire process by reducing the number of parts, shortening production cycles, and minimizing material waste. A complex aero-engine combustion chamber manufactured via traditional processes may require dozens of parts to be joined, whereas rapid prototyping can produce it as a single integrated piece. This not only reduces assembly costs but also lowers quality issues caused by assembly errors. Additionally, rapid prototyping achieves a material utilization rate of over 90%, far exceeding the less than 30% rate of traditional forging processes. For valuable materials like titanium alloys, this represents significant cost savings.

Challenges and Future Directions

Despite its widespread application in aerospace, rapid prototyping technology still faces urgent challenges. Quality consistency is a primary issue: aerospace components directly affect flight safety, requiring highly stable mechanical properties and dimensional accuracy for each part. Minute fluctuations in parameters such as temperature, pressure, and material powder particle size during rapid prototyping can impact final product quality. Thus, establishing a full-process quality monitoring system—such as real-time online inspection and big data analysis for prediction—has become a key industry task.

Expanding the range of materials is another critical direction. Currently, rapid prototyping technology primarily handles a limited range of aerospace materials, such as titanium alloys and superalloys. Molding processes for new composite materials (e.g., ceramic matrix composites, carbon-carbon composites) remain immature. These materials, with unique advantages in high-temperature resistance and corrosion resistance, are vital for future core components like aerospace engines.

Looking ahead, as artificial intelligence, digital twins, and other technologies deeply integrate with rapid prototyping, aerospace rapid prototyping will move toward “intelligence, precision, and collaboration.” For example, digital twin technology can build virtual prototyping processes to simulate and optimize parameters in advance; AI algorithms can adjust printing paths in real time to ensure stable part quality; and the establishment of distributed rapid prototyping networks will enable global aerospace enterprises to share digital models, realizing localized component production and further enhancing supply chain efficiency.

It is foreseeable that rapid prototyping technology will continue to drive manufacturing revolutions in aerospace, providing stronger technical support for human space exploration and optimized air transportation systems, and making more efficient, safer, and lower-cost aerospace products a reality.