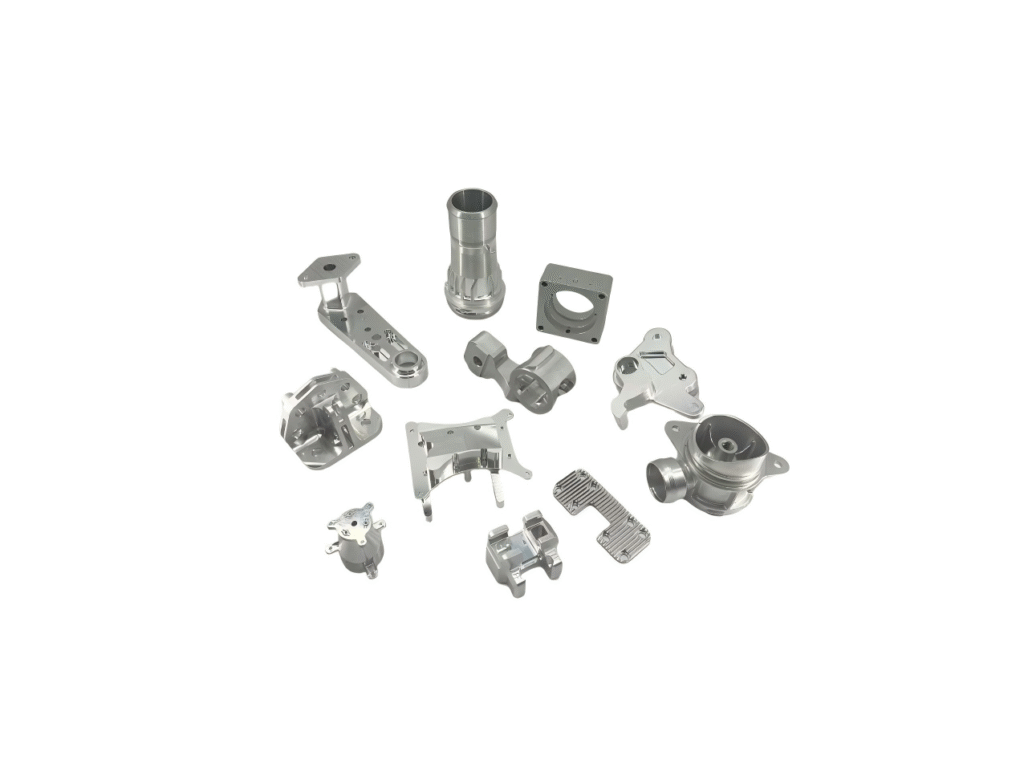

CNC Machining Services

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed computer software controls the movement of precision tools to cut, drill, and shape materials like metal, plastic, or wood. It offers high accuracy, excellent surface finishes, and is ideal for complex, high-tolerance parts.

CNC machining is widely used in aerospace, automotive, medical, and industrial sectors for high-precision components, supporting operations like milling, turning, drilling, and threading—essential for advanced manufacturing.

Different types of CNC Machining

CNC Milling

complex parts, 3-7 days delivery, guaranteed quality.

CNC Turning

Reliable, cost-effective turned components

Gantry milling

Large-part machining up to 2000×1600×700mm

CNC Milling

CNC milling is a CNC machining method. A rotating multi - point cutting tool moves along multiple axes (3, 4 or 5 axes) to remove material from a fixed workpiece on a table. Ideal for creating complex shapes, it's widely used in aerospace, automotive and electronics for high - precision parts.

CNC Turning

CNC turning is a key CNC machining process. On a CNC lathe, a rotating workpiece has material removed by a single - point cutting tool fed along X, Z (and sometimes C) axes. Efficient for cylindrical parts, it's suitable for mass - production and high - precision manufacturing in various industries.

Gantry milling