Aerospace CNC Machining:Core of Precision

In the aerospace industry, where even the smallest tolerance can determine mission success or failure, CNC (Computer Numerical Control) machining stands as a cornerstone of precision manufacturing. This technology, which automates machine tools through pre-programmed computer software, has become indispensable for producing high-performance, complex components that meet the sector’s stringent requirements for accuracy, reliability, and material integrity.

The Technical Prowess of CNC Machining in Aerospace

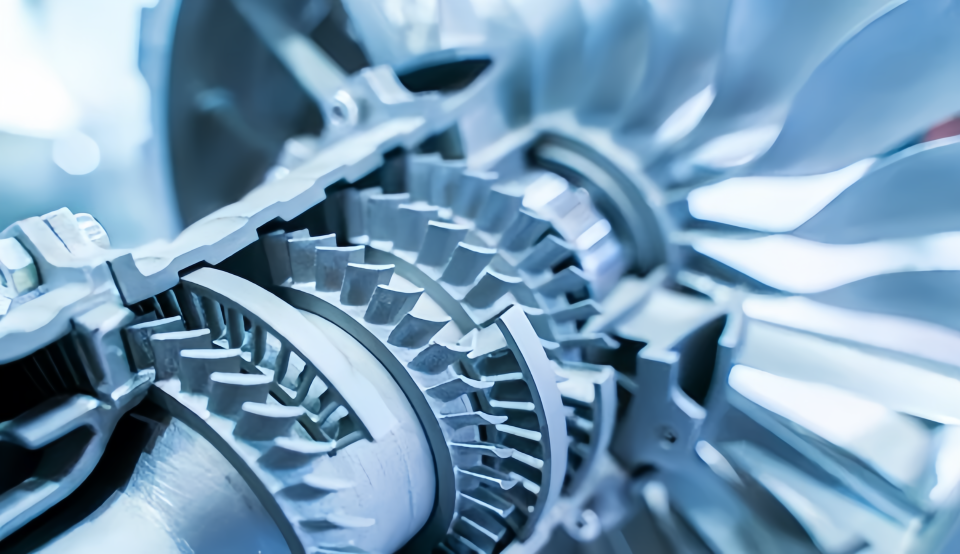

Aerospace components—such as turbine blades, structural frames, and landing gear parts—demand exceptional precision, often with tolerances as tight as ±0.001 inches. CNC machining excels in this regard, leveraging computer-controlled movements to achieve consistent accuracy across large production runs or one-off prototypes.

Unlike manual machining, which relies on operator skill and is prone to human error, CNC systems follow digital blueprints with unparalleled repeatability, ensuring every part meets exact specifications.

One of CNC machining’s key strengths is its ability to work with a wide range of aerospace-grade materials. From lightweight aluminum alloys and high-strength titanium to heat-resistant superalloys like Inconel, CNC machines—including milling centers, lathes, and multi-axis systems—can cut, drill, and shape these materials with precision. For example, 5-axis CNC mills, which rotate workpieces along multiple axes, enable the production of intricately curved surfaces on engine components, a feat nearly impossible with traditional machining methods. This versatility makes CNC machining ideal for crafting parts that must withstand extreme conditions, such as the high temperatures and pressures inside a jet engine.

Streamlining Aerospace Production Workflows

CNC machining has revolutionized aerospace manufacturing workflows by reducing lead times, minimizing waste, and enhancing scalability. In the past, producing a single complex aerospace part might require multiple setups on different machines, each operated by skilled technicians—a time-consuming process ripe for inefficiencies. CNC machining consolidates these steps: a single 5-axis machine can complete multiple operations (milling, turning, drilling) in one setup, guided by a single program. This not only cuts production time by up to 50% but also reduces the risk of errors from repeated part handling.

For large-scale production, such as manufacturing components for commercial airliners, CNC machining ensures uniformity across thousands of parts. Boeing, for instance, uses CNC systems to produce wing spars and fuselage sections for its 787 Dreamliner, maintaining consistent quality across global production facilities. For low-volume, high-complexity projects—like custom parts for military aircraft or space probes—CNC machining offers flexibility: programs can be quickly modified to adapt to design changes, eliminating the need for costly retooling.

Moreover, CNC machining integrates seamlessly with modern design tools, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. Engineers can simulate the machining process virtually, identifying potential collisions or tooling issues before physical production begins. This “digital twin” approach reduces trial-and-error, further accelerating time-to-market for new aerospace systems.

Advancing Performance and Reliability

In aerospace, where component failure can have catastrophic consequences, CNC machining plays a critical role in ensuring performance and reliability. The technology’s precision minimizes stress concentrations in parts, such as the joints of a rocket’s fuel pump, by creating smooth, consistent surfaces that distribute loads evenly. This is particularly vital for components subjected to cyclic fatigue, like aircraft wings, which must withstand millions of takeoffs and landings over their lifespan.

CNC machining also enables the production of lightweight yet strong structures through near-net-shape manufacturing. By removing material only where necessary—guided by optimized CAD models—engineers can reduce part weight without sacrificing strength. For example, CNC-machined titanium brackets in spacecraft often feature hollowed-out sections or lattice patterns, cutting weight by 20-30% compared to traditionally forged parts. This weight reduction directly translates to improved fuel efficiency for aircraft or extended mission ranges for satellites.

Furthermore, CNC machining supports the use of advanced materials that enhance aerospace performance. For instance, machining carbon fiber-reinforced polymers (CFRPs)—which are lighter than metal but equally strong—requires precise control to avoid delamination or fiber damage. CNC routers equipped with high-speed spindles and specialized cutting tools handle these materials with precision, making CFRPs viable for critical components like aircraft wings and satellite panels.

Challenges and Future Innovations

Despite its advantages, CNC machining in aerospace faces ongoing challenges. High tooling costs are a significant barrier: cutting tools for hard materials like Inconel wear quickly, requiring frequent replacement and increasing production expenses. Additionally, machining large parts—such as rocket nozzles or aircraft fuselages—demands massive CNC machines with robust structural integrity, which are costly to purchase and maintain.

Sustainability is another growing concern. Traditional CNC machining generates substantial material waste, as up to 90% of a raw metal block may be cut away to form a single part. While this is less of an issue for small, high-value components, it becomes problematic for large-scale production. To address this, the industry is adopting “near-net-shape” forging combined with CNC machining: pre-formed blanks are forged close to the final part shape, reducing the amount of material that needs to be machined away.

Looking ahead, CNC machining in aerospace is poised to integrate with emerging technologies. AI-driven adaptive machining will enable real-time adjustments to cutting parameters based on sensor data, optimizing tool life and surface finish. Digital thread systems will connect CNC machines to design software, supply chains, and quality control tools, creating a fully traceable production process—critical for aerospace’s strict regulatory requirements. Additionally, hybrid CNC machines, which combine machining with additive manufacturing (3D printing), will allow manufacturers to build parts layer-by-layer and then precision-machine critical surfaces, merging the best of both technologies.

In conclusion, CNC machining remains an irreplaceable force in aerospace manufacturing, balancing precision, efficiency, and adaptability to meet the industry’s evolving demands. As technology advances, its role will only grow—ensuring that the next generation of aircraft, rockets, and satellites are safer, lighter, and more reliable than ever before.